A Comprehensive Overview to the Various Types of Mass Plastic Containers Available Today

Bulk plastic containers play an important function in different sectors, supplying remedies for storage and transportation. Their varied kinds provide to various demands, from inflexible alternatives for strong products to versatile containers fitting different shapes. Each type offers distinct advantages, making it necessary to understand their applications and attributes. As sectors evolve, so do the demands for effective container services. What elements should one consider when choosing the best mass container?

Review of Mass Plastic Containers

Types of Bulk Plastic Containers

Bulk plastic containers come in numerous kinds, each fit to certain applications. Inflexible mass containers, versatile bulk containers, and intermediate bulk containers stand for the key categories, each offering distinct advantages. Comprehending these kinds is crucial for selecting the right container for delivering and storing materials.

Rigid Bulk Containers

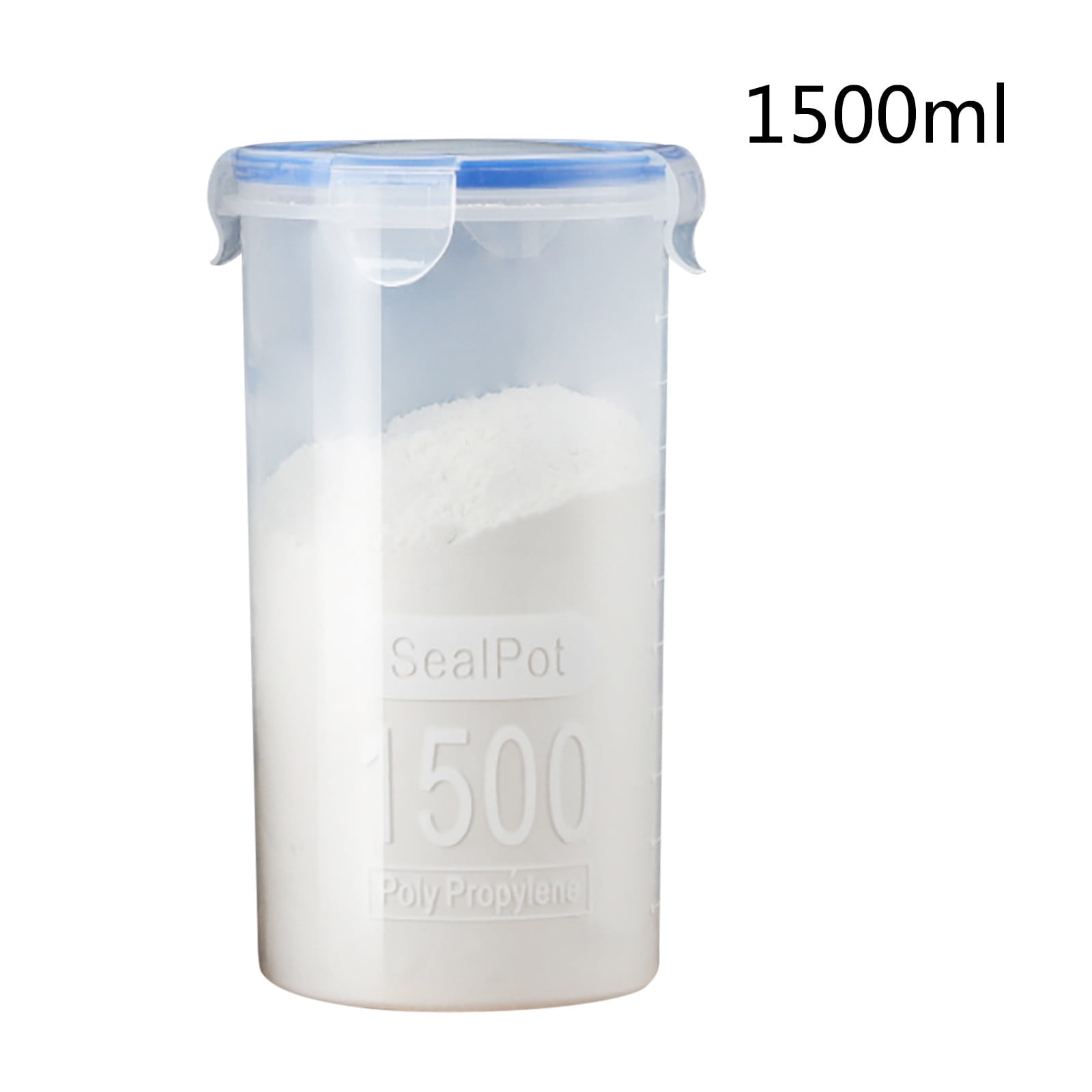

Stiff mass containers are crucial for efficient storage and transport of numerous products throughout industries. These containers are generally constructed from durable plastics, allowing them to withstand rough handling and ecological problems. They can be found in numerous forms and sizes, including containers, totes, and drums, making them ideal for storing everything from granular compounds to liquids. Stiff containers typically feature strengthened wall surfaces and safe lids, guaranteeing the contents continue to be secured during transportation. Their stackable layout makes the most of storage space, making them ideal for warehouses and making centers. Furthermore, many inflexible mass containers are recyclable and multiple-use, contributing to sustainability efforts. In general, their toughness and flexibility make rigid bulk containers an essential element in supply chain operations.

Flexible Mass Containers

Flexible bulk containers, commonly described as adaptable intermediate mass containers (FIBCs), offer as a versatile remedy for keeping a range and carrying of dry materials. These containers are commonly made from woven polypropylene and are made to be lightweight yet solid, permitting reliable handling and stacking. Their versatility enables them to fit various sizes and shapes, making them ideal for products varying from grains to chemicals. FIBCs can be equipped with functions such as spouts for easy dental filling and discharge, in addition to safety finishes for enhanced resilience. Additionally, they are reusable and recyclable, adding to lasting practices in industries like farming, food handling, and building and construction. Overall, versatile bulk containers use a efficient and affordable choice for mass product administration.

Intermediate Mass Containers

Intermediate bulk containers (IBCs) are essential for the effective transportation and storage space of fluids and granular materials across different sectors. These containers typically have a capability varying from 275 to 330 gallons and are made for easy taking care of and piling. Made from resilient materials like high-density polyethylene or steel, IBCs supply exceptional security against contamination and environmental factors. Their style consists of features such as a built-in pallet for forklift access and a removable top for simple dental filling and cleansing. IBCs are commonly utilized in chemical, food, and pharmaceutical fields, ensuring conformity with safety and security regulations. Their versatility and reusability make them an economical service for bulk storage space and transportation, adding to supply chain efficiency and sustainability.

Features and Advantages of Bulk Plastic Containers

Mass plastic containers are crucial devices in numerous markets, providing a combination of toughness and usefulness. These containers are created from top notch products, making them resistant to impacts, chemicals, and environmental variables. This effectiveness assurances product safety and security throughout storage and transportation.

Additionally, bulk plastic containers are lightweight, assisting in convenience of decreasing and managing delivery prices. Their stackable style takes full advantage of storage space performance, enabling for enhanced storehouse space. Lots of models include protected covers or closures, providing an airtight seal that maintains contents and protects against contamination.

Mass plastic containers are often multiple-use and recyclable, contributing to lasting techniques. Their adaptability enables a large range of applications, from food storage to industrial use, improving their worth throughout fields. Companies benefit from the lengthy life-span and low maintenance demands of these containers, making them an affordable option for both long-lasting and temporary demands.

Industries That Make Use Of Bulk Plastic Containers

Different sectors profit from using bulk plastic containers, each leveraging their distinct homes for details applications. The food and drink sector depends on these containers for safe storage and transport of products, while the chemical manufacturing market uses them for taking care of unsafe products. In addition, the pharmaceutical circulation requires highlight the relevance of longevity and sanitation in product packaging remedies.

Food and Drink Market

As the demand for safe and efficient storage remedies remains to climb, the food and drink sector significantly counts on bulk plastic containers for their functional demands. These containers give robust, light-weight, and versatile options for saving ingredients, finished items, and waste products. Made from food-grade products, they ensure compliance with health and safety and security criteria. Various layouts, such as stackable containers and tote boxes, maximize room during transportation and storage, enhancing logistical efficiency. Additionally, the transparency of some bulk containers allows for simple supply administration, minimizing the risk of spoilage. With the sector's concentrate on sustainability, several producers are currently using recyclable and reusable choices, aligning with eco-friendly methods while meeting the high demands of food safety and security and hygiene.

Chemical Production Industry

The chemical manufacturing market depends greatly on bulk plastic containers for the efficient and secure storage of resources, intermediates, and ended up items. These containers are developed to withstand different chemicals, making certain that dangerous materials do not leakage or degrade the container itself. Common types consist of high-density polyethylene (HDPE) and polypropylene containers, Bulk Plastic Containers which supply outstanding chemical resistance and longevity. Their lightweight nature and stackable style assist in transport and storage space, optimizing room in manufacturing facilities. In addition, numerous mass plastic containers feature features such as tamper-evident seals and easy-to-read labeling, improving safety and compliance with sector regulations. Overall, mass plastic containers are integral to the chemical manufacturing procedure, offering trusted remedies for managing varied substances.

Pharmaceutical Circulation Needs

Drug distribution depends on mass plastic containers to meet rigid safety and security and governing needs. These containers are crucial for delivering and storing a range of pharmaceutical products, including energetic pharmaceutical ingredients (APIs) and completed drugs. Their layout guarantees defense against wetness, contamination, and light, preserving the honesty of delicate products. Furthermore, bulk plastic containers are certified with market standards such as Excellent Manufacturing Practices (GMP) and are commonly made from materials that are FDA-approved. Using these containers enhances performance in the supply chain, enabling safe, large circulation while decreasing waste. Business in the pharmaceutical sector prioritize making use of sturdy, leak-proof, and tamper-evident containers to guarantee item safety and top quality throughout the logistics procedure.

Considerations for Choosing the Right Container

When picking the appropriate bulk plastic container, various variables should be thoroughly weighed to ensure optimal performance and security. The nature of the materials to be saved is paramount; compatibility with the container's product can affect stability and safety. plastic bulk containers. Furthermore, the container's shapes and size must align with the storage space and transportation needs, assuring efficient area use

Load ability is an additional vital consideration, as it should suit the weight of components without risk of damages or failing. The design functions, such as airing vent or covers, can affect usability and gain access to. Conformity with industry policies is essential, especially in fields like drugs, where safety standards are rigid.

Finally, the expected life expectancy and resilience of the container ought to be analyzed to confirm it satisfies the functional needs without frequent replacement. By assessing these aspects, one can select the most ideal bulk plastic container for specific applications.

Environmental Effect and Sustainability

As organizations increasingly focus on sustainability, the ecological influence of mass plastic containers has actually come under scrutiny. These containers, frequently made from materials such as polyethylene or polypropylene, add greatly to plastic waste if not managed correctly. Their manufacturing involves the consumption of fossil fuels, which can result in raised greenhouse gas discharges. Advancements in reusing modern technology and the click here to read advancement of naturally degradable options are assisting to alleviate these concerns.

In addition, many manufacturers are adopting methods that emphasize the use of recycled products, thereby decreasing the need for virgin plastics. The longevity of mass plastic containers also contributes; they are created to be reused multiple times, which can reduce their overall ecological impact when compared to single-use alternatives. Ultimately, the sector faces the difficulty of stabilizing functionality with eco-friendly responsibility, making lasting practices crucial for the future of bulk plastic containers.

Ideal Practices for Storage and Transportation

Reliable storage space and transportation of mass plastic containers greatly affect both functional performance and sustainability. To make best use of room, organizations ought to pile containers firmly, guaranteeing stability and stopping damages. Proper labeling is vital for very easy identification, which improves retrieval procedures. In addition, keeping a clean and organized storage area decreases the danger of contamination and boosts safety and security.

For transportation, selecting the best automobile is essential; containers should be secured to prevent moving throughout transportation. Firms need to also consider using pallets to help with less complicated loading and dumping. Regular inspections of containers for wear and tear can avoid expensive substitutes.

Temperature level control is one more vital facet, as extreme conditions can jeopardize the honesty of the plastic. Training workers on ideal techniques for managing and transportation warranties compliance and promotes a culture of safety. By implementing these ideal techniques, organizations can boost their operational effectiveness while adding to ecological sustainability.

Regularly Asked Concerns

How Do I Tidy Mass Plastic Containers Efficiently?

To tidy mass plastic containers efficiently, one should wash them with cozy water, utilize a moderate cleaning agent and scrub with a soft brush. Wash extensively, after that permit to air completely dry entirely before storage or reuse.

What Is the Life-span of Bulk Plastic Containers?

The life-span of bulk plastic containers typically varies from 5 to ten years, depending on the product, use, and environmental problems. important source Correct maintenance and storage space can substantially extend their use and toughness in time.

Can Mass Plastic Containers Be Customized?

Do Mass Plastic Containers Have Warranty Options?

Exist Rules for Using Bulk Plastic Containers?

Yes, regulations exist for using bulk plastic containers, mostly concentrated on safety, environmental influence, and product conformity. These laws assure that containers fulfill market requirements and appropriate for delivering numerous compounds safely and effectively.

Rigid bulk containers, adaptable mass containers, and intermediate mass containers stand for the main categories, each offering unique benefits. Versatile bulk containers, usually referred to as versatile intermediate bulk containers (FIBCs), offer as a flexible solution for keeping a range and delivering of completely dry products. The chemical production industry relies greatly on bulk plastic containers for the safe and reliable storage of raw products, intermediates, and finished products. Bulk Plastic Containers. These containers are created to hold up against different chemicals, making certain that harmful materials do not leak or deteriorate the container itself. Additionally, mass plastic containers are compliant with sector criteria such as Excellent Manufacturing Practices (GMP) and are frequently made from products that are FDA-approved